SILIKE Silikon-Masterbatch verhindert effektiv die Vorvernetzung und verbessert die reibungslose Extrusion von XLPE-Kabeln!

Was ist XLPE-Kabel?

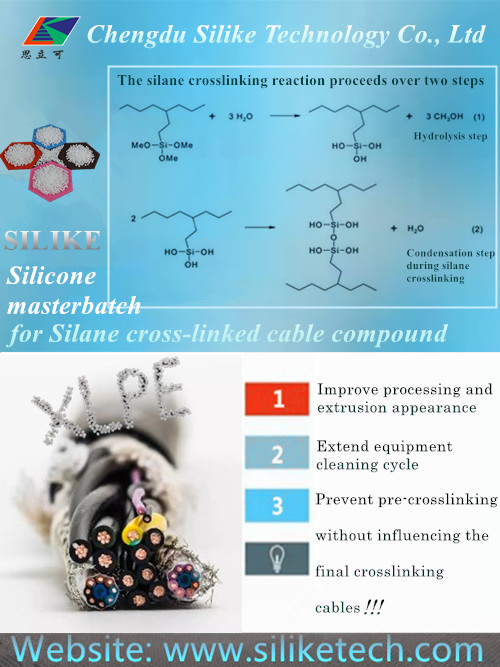

Sowohl die Peroxid- als auch die Bestrahlungsvernetzung sind jedoch mit hohen Investitionskosten verbunden. Weitere Nachteile sind das Risiko der Vorhärtung und die hohen Produktionskosten bei der Peroxidvernetzung sowie die Dickenbegrenzung bei der Bestrahlungsvernetzung. Die Silanvernetzung hingegen ist kostengünstiger, und das Ethylen-Vinyl-Silan-Copolymer kann in herkömmlichen thermoplastischen Verarbeitungsanlagen verarbeitet und geformt und anschließend vernetzt werden. Daher nutzen die meisten Draht- und Kabelhersteller die Silanvernetzung zur Herstellung ihrer XLPE-Kabel.

Für die Silanvernetzung von Compounds gibt es zwei Verfahren: das Einstufen- und das Zweistufenverfahren. Beim Einstufenverfahren werden Harze, Katalysator (organisches Zinn) und Additive wie PE bei niedriger Geschwindigkeit vermischt und anschließend zu Produkten extrudiert. Beim Zweistufenverfahren werden Katalysator (organisches Zinn) und Additive im ersten Schritt zu Masterbatches extrudiert und reagieren im zweiten Schritt mit den Harzen.

Produktionsprobleme bei vernetzten Polyethylenkabeln

Üblicherweise tritt Silanpfropfung während der Verarbeitung von silanvernetzten Kabelmischungen im Rahmen einer Vernetzungsreaktion auf. Bei unzureichender Schmierfähigkeit des Harzes haften die Mischungen leicht an der Schneckennut, bilden tote Stellen und totes Material, was das Erscheinungsbild des extrudierten Kabels beeinträchtigt (raue Oberfläche mit wenigen, während der Vernetzung entstandenen Vorvernetzungspartikeln).

Wie lässt sich eine Vorvernetzung verhindern und eine reibungslose Extrusion bei XLPE-Kabeln verbessern?

Chengdu Silike Technology ist eine Kombination aus Forschung und Entwicklung, Produktion und Handel.Silikonzusätzeseit über 15 Jahren im Bereich XLPE/HFFR-Kabelmischungen.SilikonzusätzeSie werden in Kabelmischungen zur Verbesserung der Verarbeitung und Oberflächenmodifizierung eingesetzt. Sie werden nach Südostasien, Europa, Amerika usw. exportiert.

Beim HinzufügenSILIKE Silikon-MasterbatchDie einzigartige Eigenschaft, XLPE-Kabelmischungen beizumischen, verhindert eine Vorvernetzung, ohne die endgültige Vernetzung der Kabel zu beeinträchtigen. Darüber hinaus fördert es die Plastifizierung, verbessert die Verarbeitung (z. B. Harzfluss, weniger Düsentropfen, glatte Oberfläche von Draht und Kabel nach dem Extrusionsverfahren) und verlängert die Reinigungsintervalle der Anlagen.

Veröffentlichungsdatum: 15. November 2022